2025-07-02 J&W導入人機混合自動化控制系統 提升電商倉儲效率與作業彈性

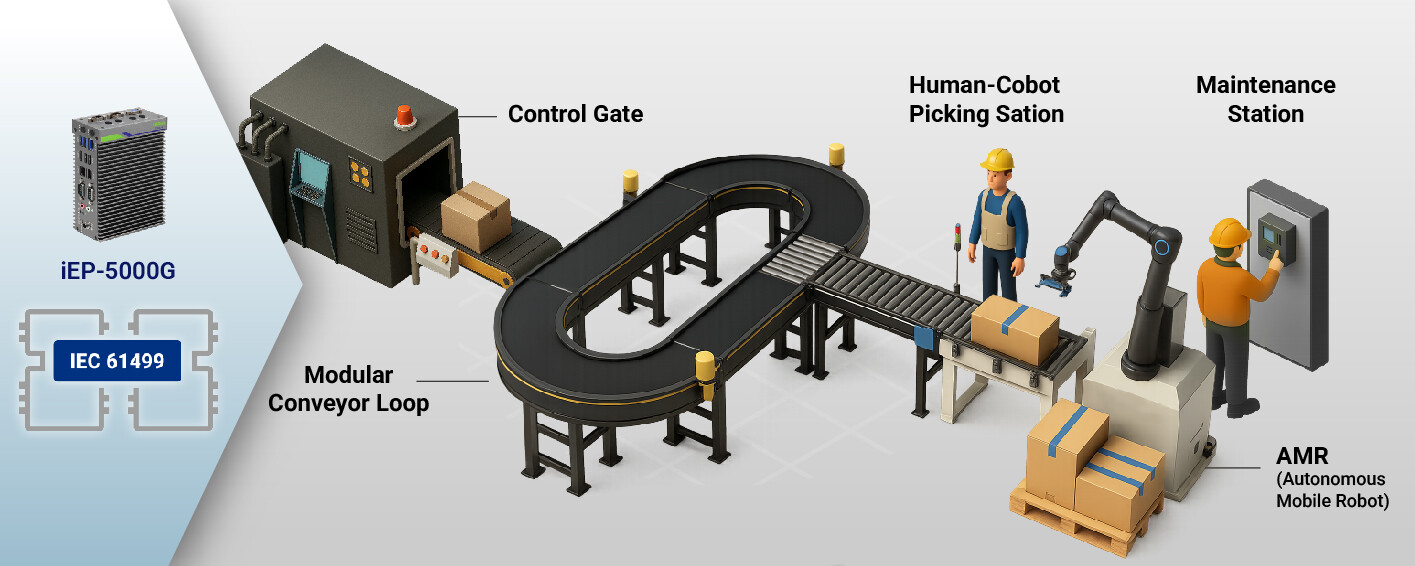

J&W採用東擎科技(ASRock Industrial)的iEP-5000G工業物聯網控制器,搭載IEC 61499控制執行環境,部署人機協作的智慧自動化系統,打造現代化電商物流中心以提升倉儲作業的效率與彈性。該系統整合模組化輸送系統與具備視覺辨識功能的控制閘門,以將貨物輸送至指定的工作站,並透過操作人員與協作機器人(Cobot)共同執行貨品揀選,並由自主移動機器人(AMRs)將貨品運送至各工作站或出貨區。透過這套系統,控制設備、機器人和資訊平台能即時協同運作,進一步強化物流流程的即時性、作業效率與系統擴展彈性。

Challenges

Challenges

An e-commerce logistics center encountered operational bottlenecks stemming from manual sorting and picking processes, where reliance on human labor increased error rates, limited throughput, and delayed order fulfillment. The existing infrastructure lacked the flexibility to accommodate evolving production demands, with any process adjustments requiring time-consuming reprogramming and causing system downtime. Additionally, the absence of seamless integration across control systems, robotic components, and enterprise IT platforms created fragmented data environments, impeding real-time decision-making and system-wide synchronization. These limitations underscored the need for a unified, intelligent solution capable of delivering adaptive automation, consistent accuracy, and scalable performance across warehouse operations.

Solution

To overcome these challenges faced by the e-commerce logistics center, J&W deployed a next-generation automation architecture built on a hybrid human-cobot (collaborative robot) system, orchestrated by ASRock Industrial’s iEP-5000G Industrial IoT Controller running the IEC 61499 runtime from UAO. The system integrates a modular conveyor loop and stations embedded with smart sensors and tags, enabling dynamic routing of goods to designated stations. Vision-enabled control gates equipped with RFID/NFC readers provide real-time items recognition and route coordination using IEC 61499 logic.

At human-cobot picking stations, cobots assist human operators in accurately picking items, optimized via the WILLIE system for enhanced human-machine Interaction. Autonomous mobile robots (AMRs) manage the transport of bins across all stations or to packing and shipping areas. A dedicated maintenance station allows system adjustments or maintenance without disrupting operations, while continuous system monitoring ensures maximum energy efficiency and uptime. This unified, edge-driven infrastructure delivers seamless coordination across control systems, robots, and IT platforms, enabling automated goods picking and handing system tailored for the demands of modern logistics centers.

Benefits

Operational Efficiency at Scale

The integrated automated system accelerates throughput and minimizes manual handling, enabling continuous, high-volume operations with reduced labor dependency.

Enhanced Accuracy and Reliability

Vision-guided picking and collaborative robotics significantly reduce error rates while maintaining consistent quality across workflows.

Future-Ready Flexibility

Powered by IEC 61499, the modular control logic allows for rapid reconfiguration and effortless scalability, ensuring alignment with evolving operational needs and digital transformation goals.

Related Product