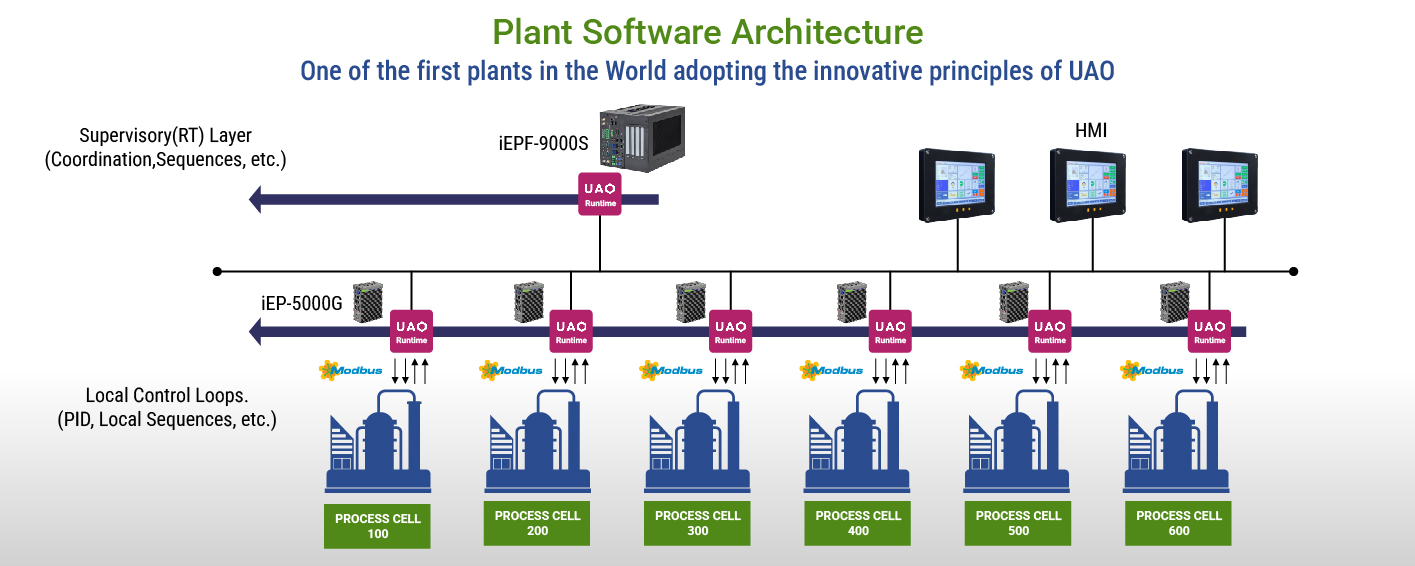

GR3N’s microwave assisted deploymerization process involves handling diverse plastic materials with varying properties, requiring a flexible and modular control system capable of adapting to frequent process changes, something traditional fixed logic systems can’t accommodate. To support flexible and scalable production, GR3N required a modular control system capable of seamless integration with advanced automation standards and robust industrial-grade hardware. Moreover, the company needed to minimize engineering costs during market expansion while safeguarding its valuable intellectual property. Additionally, enabling advanced data-driven optimizations was critical to continuously improve process efficiency. All these goals had to be achieved alongside smooth integration of operational technology (OT) and information technology (IT) systems, ensuring a unified and agile manufacturing environment.