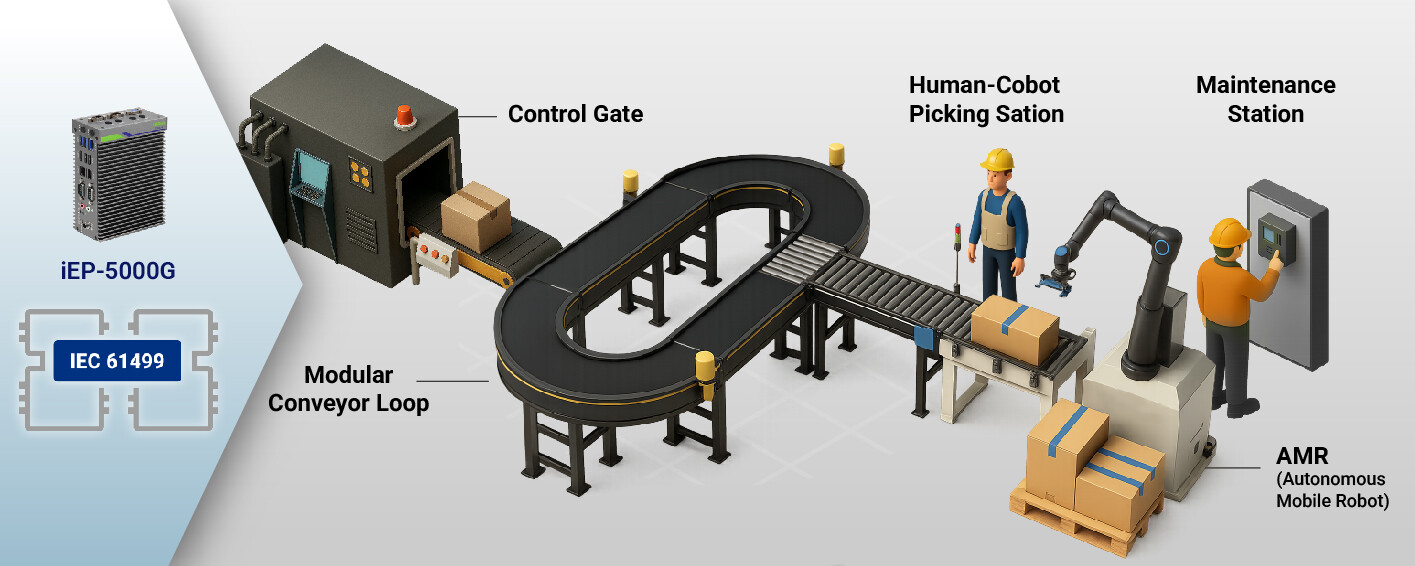

An e-commerce logistics center encountered operational bottlenecks stemming from manual sorting and picking processes, where reliance on human labor increased error rates, limited throughput, and delayed order fulfillment. The existing infrastructure lacked the flexibility to accommodate evolving production demands, with any process adjustments requiring time-consuming reprogramming and causing system downtime. Additionally, the absence of seamless integration across control systems, robotic components, and enterprise IT platforms created fragmented data environments, impeding real-time decision-making and system-wide synchronization. These limitations underscored the need for a unified, intelligent solution capable of delivering adaptive automation, consistent accuracy, and scalable performance across warehouse operations.