IC substrate manufacturing is a critical and technically demanding process within semiconductor packaging. As demand for high-performance, compact, and energy-efficient devices grows, the manufacturing needs to meet miniaturization and high-density design, stringent yield and quality control, and managing complex materials and processes. Overcoming these is crucial to ensure reliability and performance of devices across applications from consumer electronics to automotive and high-performance computing.

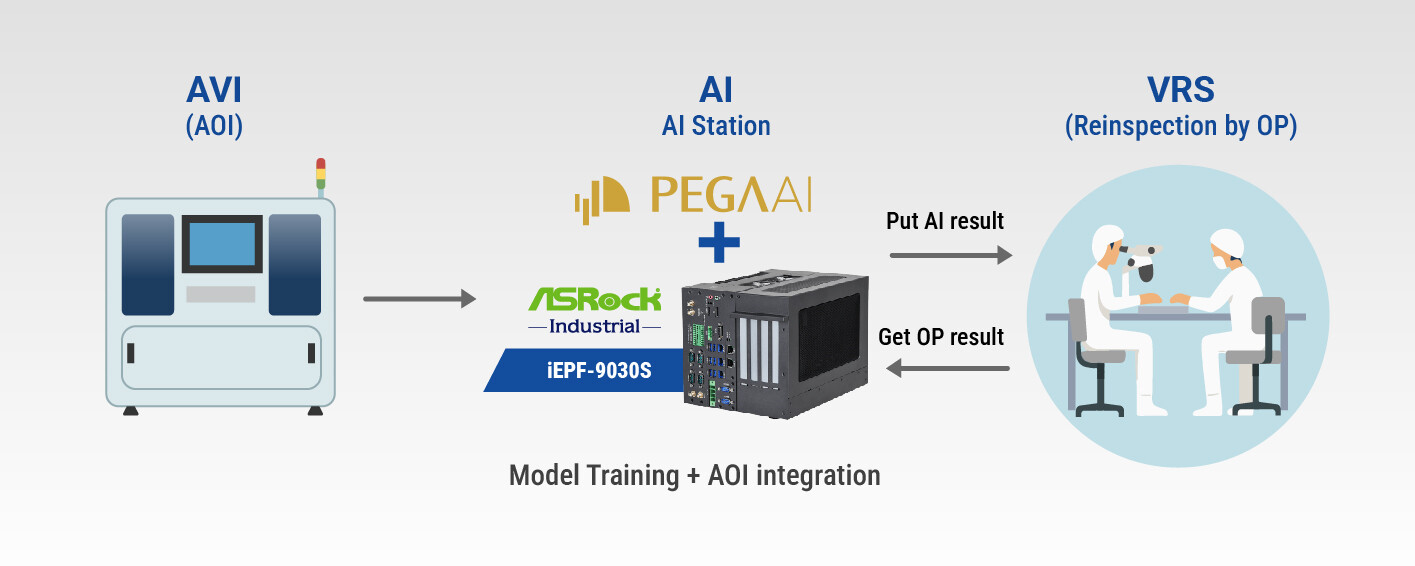

In quality control process, traditional Auto Vision Inspection (AVI) systems often generate excessive false positives commonly referred to as “overkill”, where non-defective units are misclassified, as defective. This results in an unnecessary increase in Vision Repair System (VRS) human re-inspection workload, requiring many human operators to manually review large volumes of samples that ultimately do not contain defects. The repetitive nature of human re-inspection process not only consumes substantial labor resources but also reduces inspection throughput and contributes to operator fatigue. Compounding this issue is the absence of a real-time AI integration framework capable of pre-filtering these false positives at the edge, preventing the intelligent allocation of inspection resources and limiting opportunities for process automation and continuous improvement.