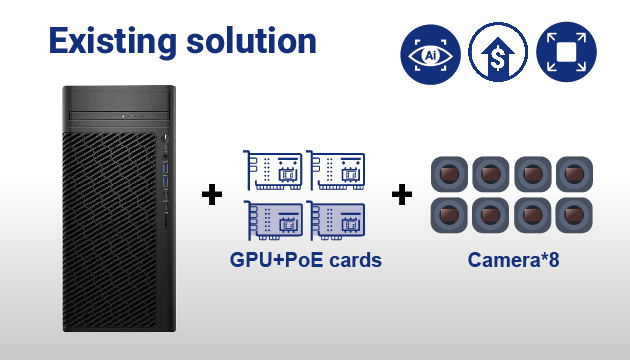

In the fast-evolving landscape of industrial automation, vision-based inspection systems must strike a balance between performance, scalability, and physical constraints. Elementary’s original vision controller was built for complex inspection scenarios involving up to eight Basler GigE cameras. While powerful, this solution demanded a dual-slot PCIe NVIDIA GPU and two 4-port PoE PCIe cards – requiring a total of four PCIe slots and resulting in a bulky, high-cost system with a large physical footprint on the factory floor. Such setups were ideal for end-of-line inspections, but became over-engineered and impractical for simpler applications involving fewer cameras.

As demand grew for more compact and cost-efficient inspection solutions, particularly for installations with limited space and simpler AI workloads, Elementary identified the need to expand its product portfolio. They required a vision controller that could handle real-time AI inference for up to two cameras, fit easily into space-restricted industrial control cabinets, consume less power, and reduce total system cost, all without compromising performance. The challenge was to maintain AI capabilities and latency targets while dramatically shrinking the size, noise, and energy consumption of the system.