Smarter and More Flexible Autonomous Mobile Robots (AMR) Reduces Labor Cost and Enhances Productivity

Smart manufacturing and distribution facilities are already being built, calling for the more intelligent Autonomous Mobile Robots (AMR) over its ancestor- automated guided vehicle (AGV). A leading IPC company accelerates the development of smart Autonomous Mobile Robots (AMR) powered by ASRock Industrial's iBOX-1185G7E to reduce labor costs and increase productivity. The AMR will become prevalent in several vertical markets such as logistics, automotive, medical, and agriculture.

挑战

The automated guided vehicle (AGV) market has become almost saturated and the next-gen AGV required enhanced AI-based navigation with high flexibility. The Autonomous Mobile Robots (AMR) market size is expected to grow from $365M to $1011M during 2020-2026 at a CAGR of about 15.9% according to MarketWatch. A leading IPC company creates smart AMR, filling the gap in industry transformation to conquer the difficulty of product development. The implementation challenges of robotic hardware include high-performance CPU and GPU for real-time AI computing and rich IOs for supporting a wide variety of sensors, vision cameras, and actuators for unlimited robotic applications. With these reliable capabilities, AMR can pick, transport, and sort items within manufacturing and distribution facilities without any manual intervention.

解决方案

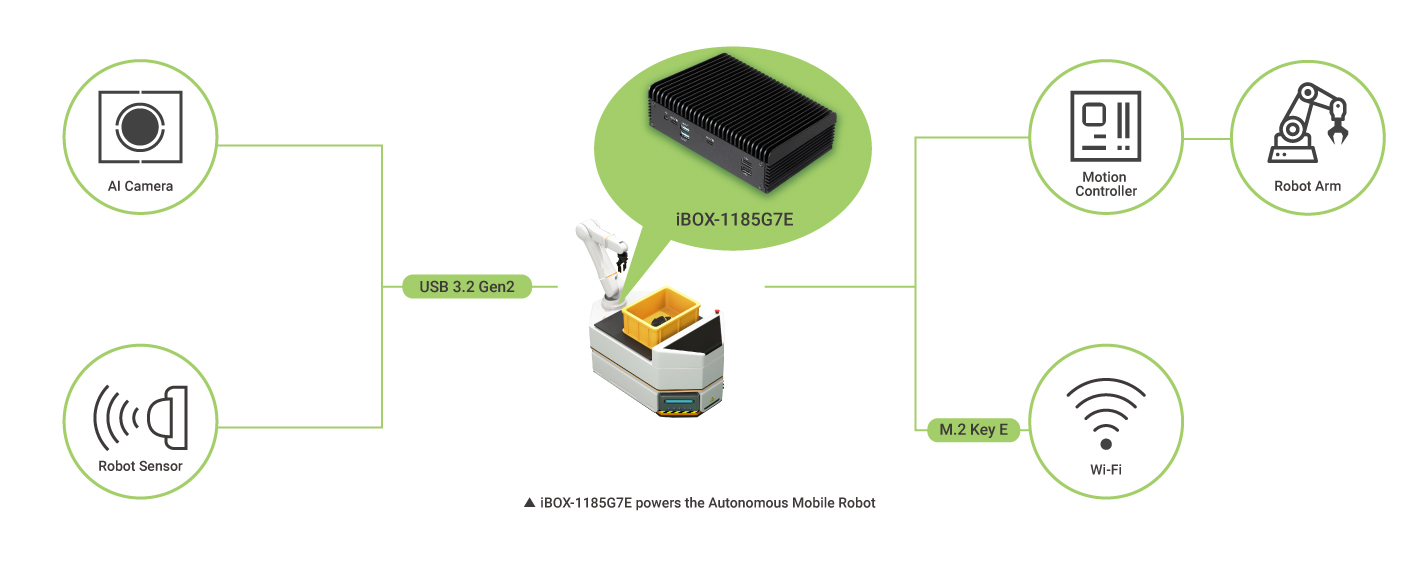

ASRock Industrial partnered with the leading IPC company to create the Autonomous Mobile Robots powered by the iBOX-1185G7E running on Intel® 11th Gen Core™ Processors (Tiger Lake-UP3) with Intel® Iris® Xe Graphics for high performance and real-time AI computing. Key features include two USB 3.2 Gen2 supporting AI Camera for smart vision and robot sensor for dynamic detection to receive critical data from its environment. Through M.2 Key E for reliable Wi-Fi connection, it ensures high-speed data transition without latency. Critical and precise motion control can also be carried out through Motion Controller to connect and control the Robotic Arm. With feature-rich IOs connectivity and AI capability at 4.15 TFLOPS and 8.29 TOPS, it supports a wide variety of sensors and actuators to enable the Autonomous Mobile Robots to perform AI-based navigations.

|

AI Capability |

Execution Units |

TFLOPS (FP16) |

TOPS (INT8) |

|

iBOX-1185G7E |

96 EU |

4.15 |

8.29 |

|

iBOX-1145G7E |

80 EU |

3.45 |

6.9 |

|

iBOX-1115G4E |

48 EU |

2.07 |

4.14 |

▲ AI Capability of iBOX 1100 Series

引进效益

Accelerates the development of AMR:

The iBOX-1185G7E powered by Intel® 11th Gen Core™ CPU and Intel® Iris® Xe Graphics enables real-time AI navigation and accelerates the development of AMR.

Reduce labor cost and increase productivity:

With iBOX-1185G7E upgrades, the AMR can be effectively deployed to perform repeated tasks and carry heavy loads under factory and warehouse operations. This reduces the cost of human labor, increases work productivity, and embraces the future of unimaginable proficiencies.

Smart AI-based navigation:

Intelligent path planning and sensing capabilities allow for smart navigation, replacing tapes, track labels, or QR codes required by traditional AGV. This drastically increases efficiency and flexibility for stationed workers.